When it comes to LED off-road lights, people often focus on factors such as power, light beam pattern, and lifespan, which are undeniable considerations. However, some seemingly inconspicuous small devices also play a decisive role in the perfection and quality of a product. This essay will introduce you to the inconspicuous but important part of off-road lights—the breather valve.

Initially, breather valves were primarily used in products such as footwear, clothing, tents, and sleeping bags designed to be waterproof and windproof. These products were made using materials and processes that involved covering the fabric with a waterproof adhesive to achieve water and wind resistance. After the development of the second generation of PU (Polyurethane), the third generation of TPU (Thermoplastic Polyurethane), and ultimately the use of PTFE (Poly Tetra Fluoro Ethylene), the latest generation of waterproof and breathable materials, their waterproof and breathable performance experienced significant development. Due to the excellent waterproof and breathable effect, high and low-temperature resistance, corrosion resistance, and other characteristics of the breather valve, it is widely used in the automotive lighting industry, outdoor lighting fixtures, sensor equipment, communication equipment, precision electronics industry, solar energy equipment, and other fields.

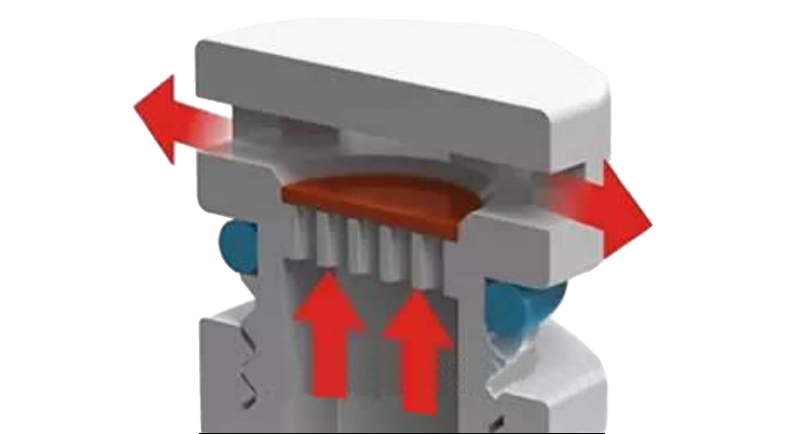

A breather valve for LED lights, also known as a waterproof breather valve, is an accessory for LED lighting. It is a waterproof breathable membrane formed through injection molding, ultrasonic welding, overfitting, and other forms, combining plastic, metal, silicone, and other materials to create a sealed installation part.

So, how does the breather valve work?

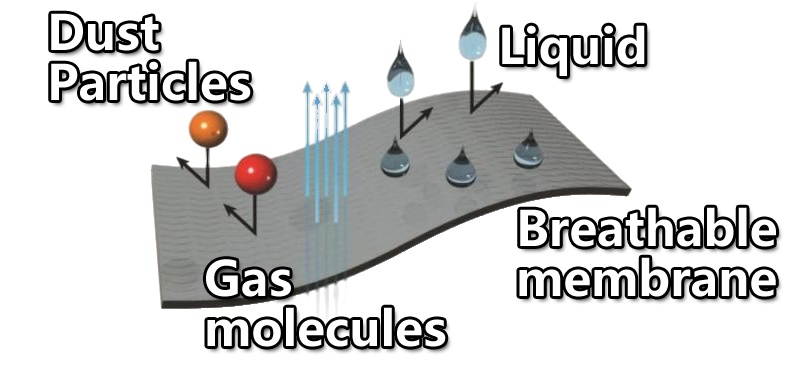

The breather valve has a large air permeability, a fine porous structure of the waterproof and dustproof breathable membrane. This breathable membrane has very high air permeability, allowing continuous exchange of gases between the inside and outside of the cover, preventing high temperature and pressure inside the cover from impacting the lamps and lanterns.

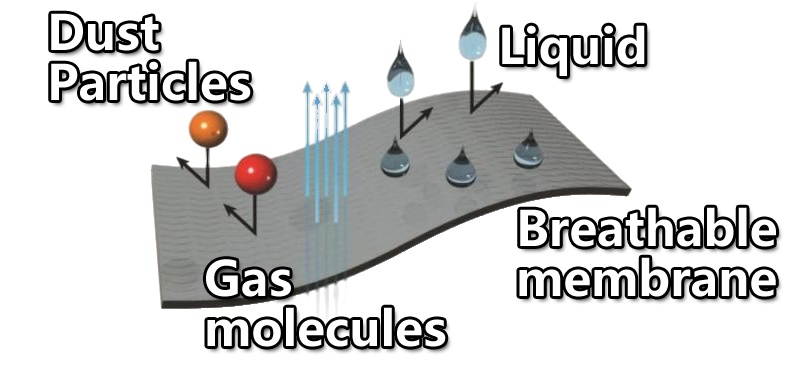

The breathable membrane has a microporous structure, using the difference in volume size and number between gas molecules and liquid and dust particles to achieve waterproof and breathable purposes. In the state of water vapor, the water particles are so small that they can smoothly penetrate to the other side, leading to the phenomenon of vapor permeability. When water vapor condenses into water droplets, the particles become larger, and due to the surface tension of the water droplets, water molecules cannot successfully penetrate to the other side, preventing water infiltration. Additionally, the water-repellent structure of the waterproof and breathable material prevents water, dust, and insects from penetrating the interior of the housing.

Lamps are subject to various factors during operation, such as ambient temperature, internal and external temperature differences, pressure differences, dust, dirt, and moisture, which may adversely affect the performance of the lamps. In particular, the pressure difference between the inside and outside can cause damage to the sealing parts of the lamps. When the LED lamp is lit, it converts most of the electrical energy into heat, gradually increasing the internal temperature of the lampshade. This increase in temperature raises the air pressure inside the lampshade, exerting greater pressure on the inner wall of the lampshade cavity. When the lamp is turned off, a certain negative pressure usually forms in the lampshade cavity. All these phenomena can damage the structure of the lamp and reduce its service life.

Therefore, the provision of a breather valve on the housing of the luminaire cover enables the pressure inside and outside the cover to quickly equalize in response to changes in ambient temperature and pressure, thus reducing the impact on the pressure exerted on the cover and internal parts.

The following are the functions of the breather valve:

Waterproof, dustproof, oilproof, with a protection level up to IP68.

Prevention of condensation and fogging, improving the service life of the product.

Dissipation of heat and balancing of differential pressure to improve the integrity of the product.

Resistance to chemical agents, high and low temperatures, anti-aging, etc., improving the reliability of the product in harsh environments.

OGA work lights, light bars, off-road lights, and other high and low-power LED lights all feature a breather valve design, effectively improving the quality of the product and extending the service life of the LED lamps. Choosing a better product allows you to be more at ease.