Your location: Home > NEWS > INDUSTRY NEWS

Since 1898, the Columbia car in the United States has been using electric lights as headlights and taillights for the first time. Automotive lamps have a history of over 100 years of development. With the use of new materials, continuous innovation in processing technology, and the ongoing improvement of people's aesthetic and aerodynamic requirements for automobile appearance, automotive lamps have evolved from simple functional parts to an integral component of automotive modeling design. As a visual element and functional signal light, the issue of headlight fog has long perplexed designers and engineers, representing a focal point for their ongoing efforts to resolve.

The formation of fog can have a significant impact on the performance of car headlights. The scattering and absorption of water beads on the light can lead to deviations and disorders in optical performance, affecting the overall aesthetic appeal of the vehicle and the driver's visibility. In more serious cases, it can also compromise driving safety. Additionally, fog beads can accelerate the aging of lighting materials, shorten the lifespan of lamps, and potentially corrode circuit boards, leading to light failure. According to relevant data, approximately 30% of lamp failures are attributed to fog-related issues. Customer complaints regarding headlight fog problems have consistently ranked as a top after-sales concern for an extended period.

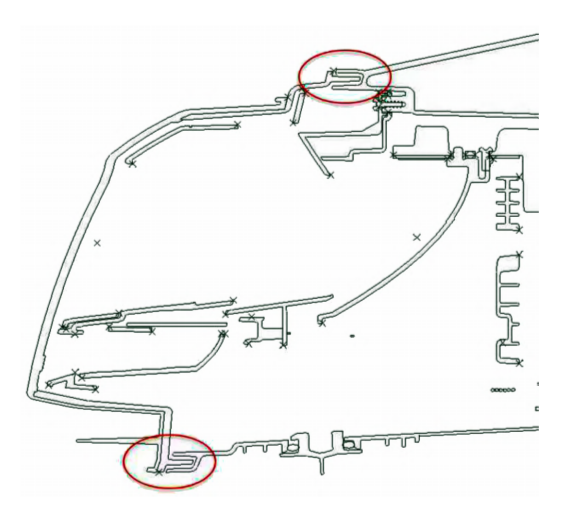

The phenomenon of fogging in car lights is generally defined as the appearance of fog in localized areas of the lamp body, which automatically disappears after the lamp has been in operation for a period of time. However, if there is extensive water condensation or accumulation on both the exterior and interior surfaces, resulting in flowing along these surfaces (refer to Figure 1), or if there is water pooling inside the lamp chamber (refer to Figure 2), such a phenomenon should no longer be referred to as fogging. This indicates a problem of water leakage caused by the quality of the lamp body, and it is essential to promptly repair or replace the lamp so as not to compromise driving safety.

Conventional water leakage problems can be attributed to several factors:

The formation of fog is essentially the physical phenomenon of water vapor condensing into small water droplets under specific conditions. This liquefaction can occur through two methods: either by reducing the temperature or by altering the pressure. In the case of a lamp, where there are air holes in the body and the air pressure inside matches that of the external environment, fog forms when moisture condenses within the chamber and attaches to its surfaces due to changes in thermal fields. For water vapor to condense into fog, three conditions must be met: there must be a sufficient concentration of water vapor, a condensation core must be present, and the temperature must be lower than the critical temperature for water vapor condensation.

Based on these principles, it can be concluded that factors leading to water vapor condensation within a lamp chamber include: having a medium acting as a condensation core inside the lamp or having uneven surfaces serving as potential sites for condensation; maintaining regions with temperatures below the critical point for water vapor; and ensuring high concentrations of water vapor within the lamp chamber.

Currently, the processing technology of parts faces challenges in preventing the presence of condensation nuclei on the surface of parts. The lamp body is not completely sealed, making it difficult to ensure the absence of condensation core medium inside the lamp chamber. Additionally, heating components such as circuit boards and dimming motors generate heat, and external ambient temperature fluctuations make it challenging to maintain a consistent internal temperature within the lamp chamber. When the lights are turned off after operation, temperature changes cause internal and external gas exchange, inevitably introducing moist gas into the lamp chamber. As a result, fogging issues cannot be fully resolved; only corresponding measures can be taken for optimization.

After analyzing the conditions for the formation of fog in lamps, it is evident that the distribution of temperature field, air flow, humidity distribution inside the lamp chamber, material properties of lamp body parts, and air purity inside the lamp chamber are the main factors affecting fog formation. The uneven distribution of temperature field leads to local temperature increases when the lamp is lit, causing air convection and moisture condensation in areas with lower temperatures, resulting in fog. Additionally, dead angles of air flow can trap water vapor during convection, further contributing to fog formation. Currently, most lamps are designed with air vents and dustproof sponges to prevent external dust from entering the interior of the lamp chamber; however, adding a dustproof sponge may affect air fluidity. Lamp manufacturers have also improved cleanliness by using higher level clean rooms for production and installation. In general, a more uniform temperature field distribution within the lamp body results in greater air fluidity and lower water vapor concentration—reducing fog formation.

When designing lamps, designers should consider how modeling design influences airflow fields as well as temperature and water vapor distributions within the lamp chamber. It is important to avoid unfavorable modeling and structures that could impact these physical fields.