Hi friends,

Are you ready for the upgraded version of 3012 street legal series 3 inches LED light pods? Let us highlight the new features and improvements for you!

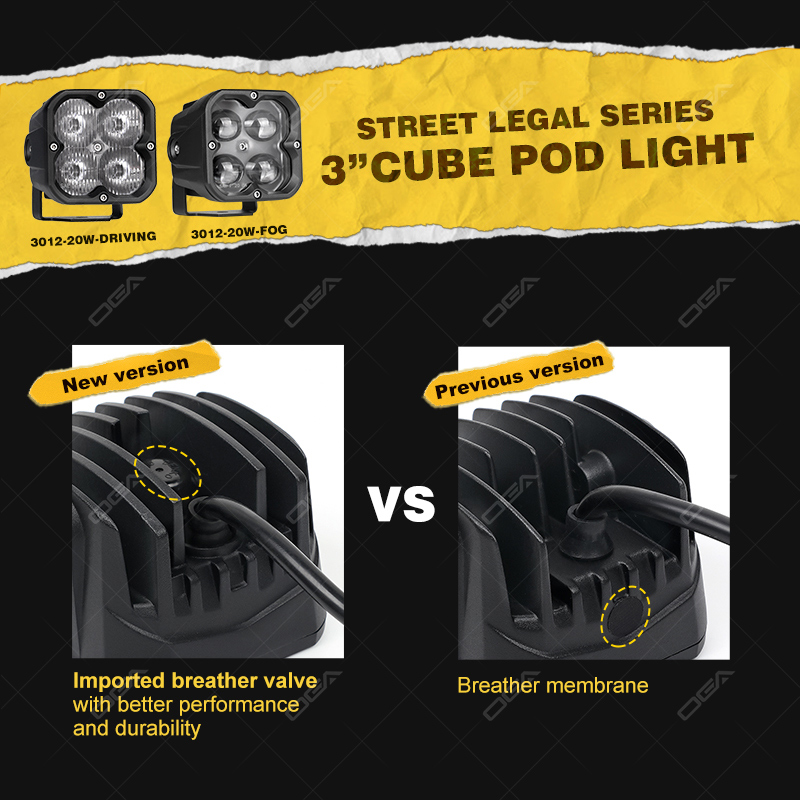

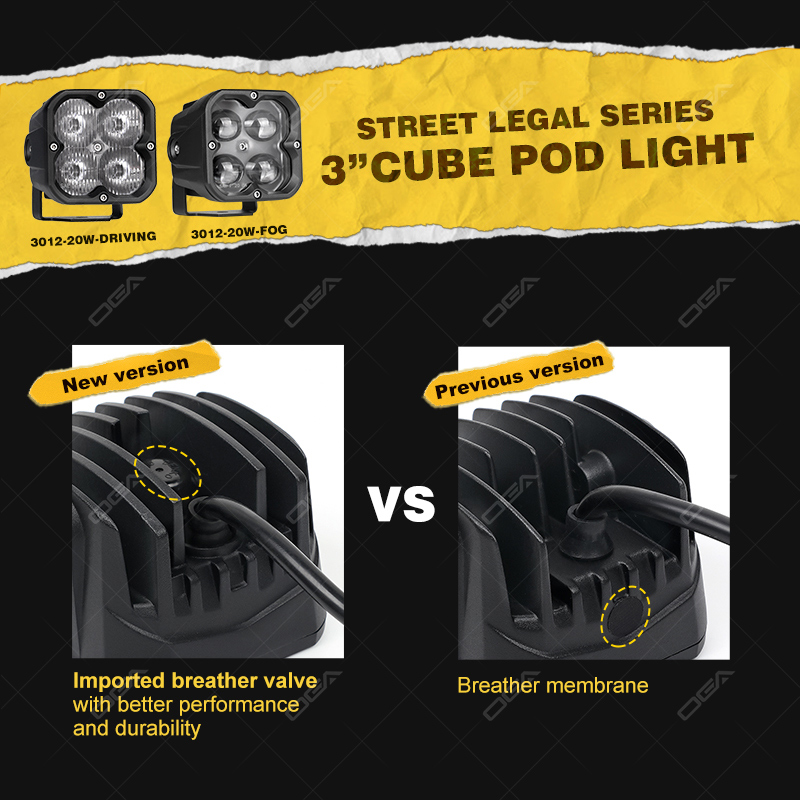

1. Adoption of the imported breather valve instead of using a breather membrane for better performance and durability.

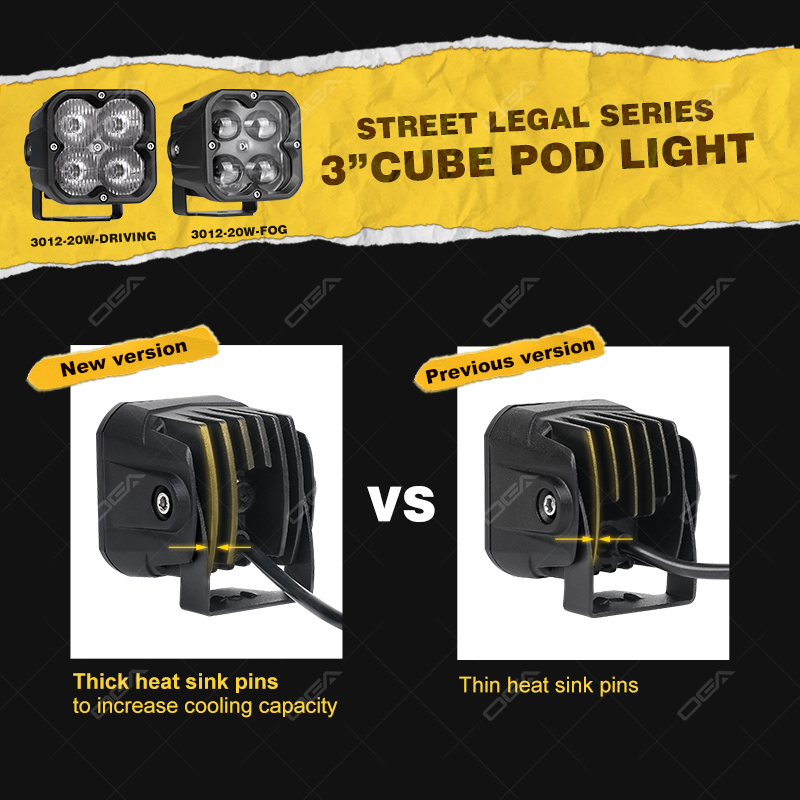

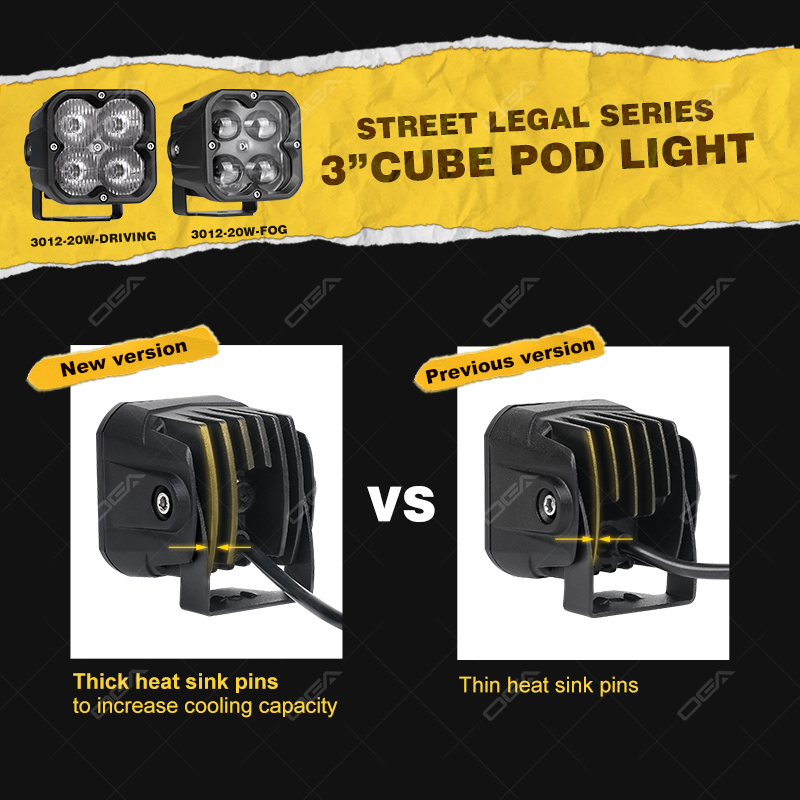

2. Thicker heat sink pins design for larger cooling capacity.

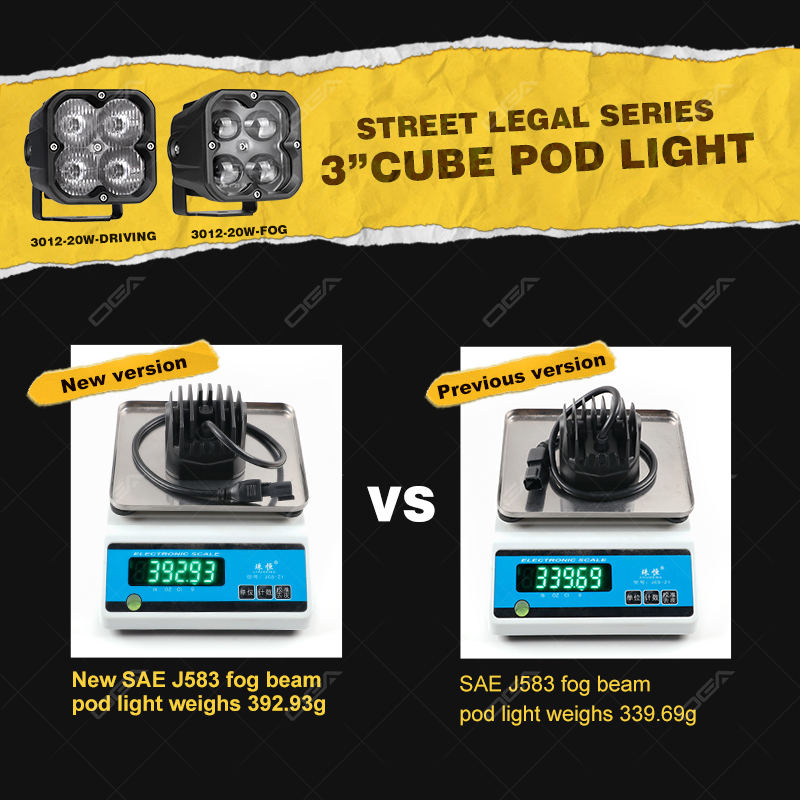

3. Housing weight increased (for example, fog light pod increased from 339.68g to 392.93g), more solid construction to withstand harsh conditions.

OGA never stops developing better products and offering better solutions for our clients!

Automotive LED lamps are used either on paved roads or off-roading, which means they are more likely going to be exposed to various weather changes phenomena such as rain, dust, snow, strong winds, and high temperature. And so, structural strength, sealing, waterproof, dust-proof, heat dissipation and anti-aging, etc., these features will be counted into consideration when designing the structure of an automotive LED light.

The Problem We Were Facing While Developing the Structure of the 3012 Series LED Work Lights

To the surprise of many, most of the electricity in an LED chip becomes heat rather than light (about 70% heat and 30% light), and so the generated heat must be channeled away from the LED chips into the ambient with heat transfer technologies to avoid imminent mechanical failure or significant drop of performance. And yet in the meantime, it is important to keep all electrical appliances away from water, and so, the inside and outside of an automotive LED lamp needed to be completely isolated for good waterproof sealing. But if that is the case, the internal and the external air is not going to be interchangeable, as we said before, the generated heat must be channeled away from the LED chips, so we usually increase the external cooling area, and that is radiating heat sink. But even so, the thermal transmission of the air is week, once the LED chips start working, the internal temperature of the lamps is going to be much higher than the external, not only the high temperature could potentially damage the internal electronic components of the lamps but also the atmospheric pressure difference between internal and external could potentially damage the housing, therefore the lamp is more likely going to fail. Such as above are the contradictions in functionality and structure of an automotive LED lamp, at the same time, it is also a problem of structure seal (waterproof) and air exchange.

The General Solution

Any lighting equipment is a living machine, it moves and turns, shakes, gets sick, overheats, and yes even breath. As the lighting equipment heats up and cools down, it expands and contracts. And in order to keep the lighting equipment from build up too much pressure, lighting equipment OEMs include vent caps on the fill port to allow expanded air to escape. There is only one problem, while they let the air out, those simple caps do not prevent small dirt particles and moisture from making their way into the equipment, which can cause big problems. Dirt particles as small as 5 microns can damage valves by wearing away the critical surfaces, even worse, moisture over time will condense inside the lighting equipment, dimming the lighting output and over time, damaging the lighting equipment.

Our Solution

But there is where waterproof breather membrane and waterproof breather valve work their magic, breather membrane and breather valve are used to prevent moisture and even the smallest particles from entering the lighting equipment with multiple layer filtration. A waterproof breather valve or waterproof breather membrane just as its name implies is waterproof and breathable which means the air can freely go through when there is the differential pressure between the inside and outside of the lighting equipment. When the internal pressure of the lamp is bigger than external, the air will be externally discharged, and so the interior heat will also be dissipated; The internal pressure is going to be smaller than the external pressure once the light is off, and the relatively cool air will go back into the lamp, but with multiple layer filtration, the external water or moisture cannot enter the lamps, therefore achieve air pressure balance and temperature between the internal and external, solving the problem of the structure seal (waterproof) and air exchange.

What are Breather Membranes?

Breather Membranes (or breathable membranes) are water-resistant but vapor permeable. Typically, they are used within the external wall and roof constructions of lighting equipment, where the external cladding may not be completely water-tight or moisture resistant. The breather membranes we used are specifically for automotive lamps to quickly discharge pressure and moisture in the lamp with excellent properties such as waterproofing, dust-proofing, and oil-repellent. They provide impressive airtightness, whilst offering exceptional water vapor transmission.

How Breather Valve Is Better Than Breather Membrane?

If you plan to do regular off-roading that includes a lot of water crossings, making sure your lights have a breather valve. Because wading in water with hot lamps causes pressure changes and a rapid decrease in temperature, this can cause the air in the lamp to condense. Breather valves are the new standard in the most professional way to keep your lamps dry, using a waterproof but breathable fabric to allow the pressure to equalize and overcome this condensation issue. We do not recommend automotive LED light that uses breather membranes, because they are not efficient enough for this kind of rapid changes, let alone the traditional breather membranes often time just stick on rather than bolt on, the breather membranes could potentially fall off after a certain amount of rough use, and leaving a big hole at the back of the lamp housing.

Main Advantages of The Upgraded Version

1. Highly efficient breathability: Reduce fogging sharply on lamps; Rapid Balance the inside and outside differential pressure; Fast balance the inside and outside temperature difference to control light failure.

2. High waterproof and anti-dust performance grade: prevent water, oil, dirt, etc. into the lamp to protect the interior electronic component, decrease failure rate, prolong the service time.

In addition, we also thicken heat sink pins for a larger cooling capacity.

Why Are Heat Sink Pins So Important to Heat Dissipate System?

Heat sink pins are needed to control the temperature around lighting equipment and can be important in facilitating a long lifespan for the product. When the design of equipment does not act effectively to distribute unwanted heat away into the external ambient, the generated heat would be channeled away from the LED chips into the external ambient with heat sink pins. They absorb excess heat then dissipates it away. They are commonly used in lighting equipment because the high temperature from the luminaire can degrade the working lifespan of the product. LED is a great technology as the light gives off far less heat, which helps preserve the product, but good heat sink pins are important as they help preserve lifespan further.

OGA's 3012 series LED work lights are a great example of a luminaire with highly efficient heat sink pins, using an advanced design aluminum multi-fin heat sink pins system.

Because of above all that, the housing weight of the 3012 series LED work lights are going to slightly increase, but do not worry, they are as solid and durable as before, or even better in harsh conditions. What are you still waiting for, send us your inquiry for a sample test to see if they truly live up to what we have described.